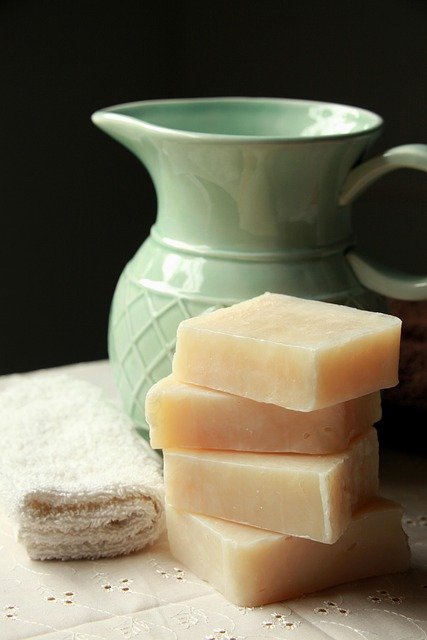

How Bar Soaps Are Made and Why People Use Them

Bar soaps have been used for hundreds of years to help clean our skin. They come in many shapes, colors, and scents. In this article, we will explore how bar soaps are made, what ingredients are commonly used, and how they have changed over time. You will learn about the steps of soap making, the different types of oils and fats used, and why so many people enjoy using bar soap every day.

The creation of bar soap represents one of humanity’s oldest chemical processes, transforming simple ingredients into essential hygiene products through a method called saponification. This process occurs when fats or oils react with an alkali substance, typically sodium hydroxide, creating soap molecules that can effectively remove dirt and oils from skin.

What Is the Bar Soap Making Process

The bar soap making process begins with selecting base oils and fats, which determine the soap’s final properties. Common ingredients include coconut oil for lather, olive oil for mildness, and palm oil for hardness. The cold process method involves mixing these oils with a carefully measured sodium hydroxide solution at specific temperatures. As the mixture thickens through saponification, additional ingredients like fragrances, colors, or exfoliants can be incorporated before pouring into molds. The hot process method accelerates saponification by applying heat, allowing for immediate use after cooling, though cold process bars typically require 4-6 weeks of curing for optimal quality.

Which Natural Bar Soap Ingredients Are Most Common

Natural bar soap ingredients form the foundation of quality soap making, with each component serving specific purposes. Base oils like coconut, olive, castor, and palm provide different characteristics - coconut creates rich lather, olive oil offers moisturizing properties, and castor oil contributes to creamy bubbles. Natural additives include essential oils for fragrance, botanical extracts for skin benefits, and natural colorants like turmeric or spirulina. Clay, oatmeal, and sea salt serve as gentle exfoliants, while shea butter and cocoa butter enhance moisturizing properties. Glycerin, a natural byproduct of saponification, helps maintain skin hydration.

How Bar Soap Manufacturing Has Evolved

Modern bar soap manufacturing combines traditional saponification with advanced technology and quality control. Industrial production utilizes continuous saponification processes where oils and alkali are mixed in precise ratios using automated systems. The mixture undergoes controlled heating and cooling cycles before being extruded, cut, and stamped into final shapes. Quality testing ensures proper pH levels, moisture content, and consistency. Large-scale manufacturers often use synthetic detergents alongside traditional soap bases to create specific properties like antibacterial action or enhanced lather.

What Types of Bar Soap Serve Different Purposes

Different types of bar soap cater to various skin needs and preferences. Castile soap, made primarily from olive oil, offers gentle cleansing for sensitive skin. Glycerin soaps provide extra moisture retention, while antibacterial soaps contain antimicrobial agents for enhanced germ protection. Exfoliating bars incorporate pumice, oatmeal, or other abrasives for removing dead skin cells. Specialty soaps include those formulated for specific skin conditions, such as tea tree oil bars for acne-prone skin or sulfur soaps for certain dermatological issues. Artisan soaps often feature unique ingredient combinations and artistic designs.

Understanding the History of Bar Soap Development

The history of bar soap spans millennia, beginning with ancient Babylonians who discovered that mixing animal fats with wood ash created a cleansing substance around 2800 BCE. Ancient Egyptians and Romans refined these techniques, with Romans establishing the first soap-making guilds. Medieval European monasteries became centers of soap production, developing recipes that remained largely unchanged for centuries. The Industrial Revolution mechanized soap production, while the 20th century introduced synthetic detergents and specialized formulations. Today’s soap making balances traditional methods with modern safety standards and environmental considerations.

| Soap Type | Primary Ingredients | Cost Estimation | Key Benefits |

|---|---|---|---|

| Castile Soap | Olive oil, sodium hydroxide | $3-8 per bar | Gentle, moisturizing |

| Glycerin Soap | Glycerin, soap base | $2-6 per bar | Hydrating, transparent |

| Coconut Oil Soap | Coconut oil, lye | $4-10 per bar | Rich lather, cleansing |

| Goat Milk Soap | Goat milk, oils, lye | $5-12 per bar | Moisturizing, gentle |

| Charcoal Soap | Activated charcoal, oils | $6-15 per bar | Detoxifying, deep cleansing |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Bar soap continues to evolve as consumers increasingly seek natural, sustainable alternatives to liquid cleansers. The resurgence of artisan soap making reflects growing interest in understanding ingredient origins and supporting local businesses. Environmental benefits include reduced plastic packaging compared to liquid soaps and biodegradable formulations that minimize ecological impact. As manufacturing techniques advance, bar soaps maintain their position as effective, economical, and environmentally conscious choices for personal hygiene, proving that sometimes the oldest solutions remain among the best.