How 3D Printers Work and What They Can Create

3D printers are machines that can make real objects from digital designs. They work by building shapes layer by layer. People use them to create models, toys, tools, and even art. Learning about 3D printers helps you understand how ideas can turn into things you can touch.

What is 3D Printing Technology?

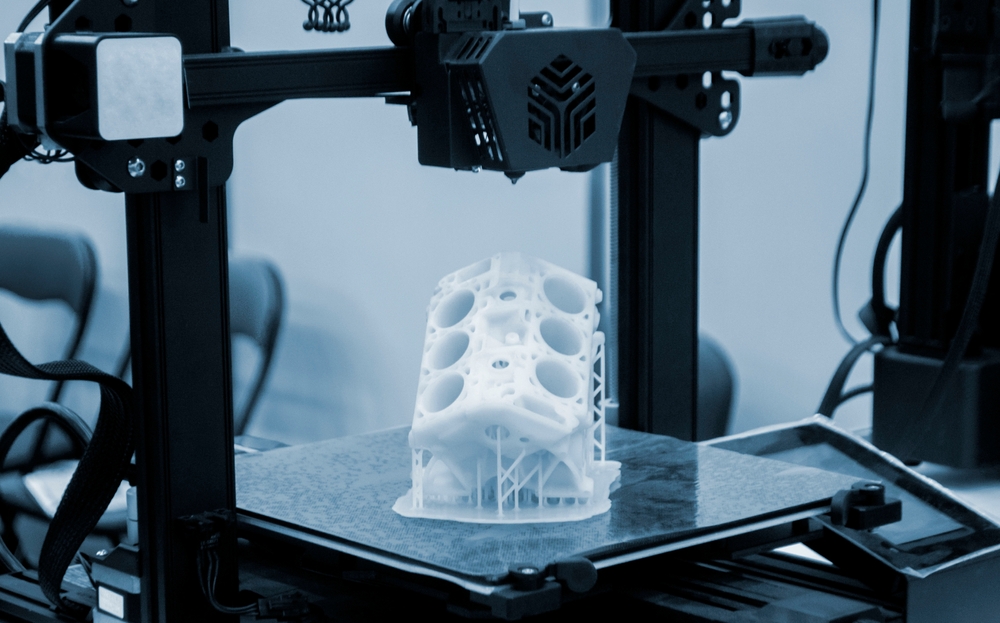

Additive manufacturing, commonly known as 3D printing, is a digital fabrication technique that constructs three-dimensional objects by depositing materials layer by layer. Unlike traditional manufacturing methods that cut or remove material, 3D printing builds objects from the ground up, allowing for complex geometries and customized designs that would be impossible with conventional techniques.

How Do 3D Printers Actually Work?

The core process of 3D printing begins with a digital 3D model created using computer-aided design (CAD) software. This model is then sliced into hundreds or thousands of thin horizontal layers by specialized software. The 3D printer reads these layer instructions and systematically builds the object by depositing material - which can include plastics, metals, ceramics, or even biological materials - with remarkable accuracy.

Types of 3D Printer Models

Different 3D printing technologies exist to suit various applications:

-

Fused Deposition Modeling (FDM): Uses melted plastic filament

-

Stereolithography (SLA): Employs liquid resin cured by laser

-

Selective Laser Sintering (SLS): Fuses powdered materials with lasers

-

Digital Light Processing (DLP): Similar to SLA but uses digital light projection

Common Applications of Digital Fabrication

3D printing has transformed multiple sectors:

-

Healthcare: Custom prosthetics, dental implants, anatomical models

-

Manufacturing: Rapid prototyping, complex machine parts

-

Architecture: Scale models, design visualization

-

Aerospace: Lightweight, complex component creation

-

Education: Interactive learning tools and models

Pricing and 3D Printer Options

| Printer Type | Price Range | Best For |

|---|---|---|

| Entry-Level FDM | $200-$500 | Hobbyists, Beginners |

| Mid-Range SLA | $500-$2,000 | Detailed Prototyping |

| Professional SLS | $5,000-$50,000 | Industrial Applications |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Getting Started with 3D Printing for Beginners

Newcomers to 3D printing should start with user-friendly, affordable models and focus on learning basic design skills. Online tutorials, community forums, and maker spaces provide excellent resources for understanding this transformative technology.

3D printing continues to evolve, offering unprecedented opportunities for innovation across numerous fields. As technology advances, these digital fabrication techniques will undoubtedly become more accessible, precise, and integral to modern design and manufacturing processes.